Elythor, a startup born out of EPFL, has recently introduced an innovative drone that possesses the remarkable ability to dynamically adjust its wing shape in response to varying wind conditions and flight positions. This groundbreaking feature significantly reduces the drone’s energy consumption while enhancing its overall performance. Furthermore, the drone’s wings can change their position, enabling it to seamlessly transition between vertical and horizontal flight. These exceptional characteristics make it an ideal candidate for conducting inspections in power plants.

Throughout history, humans have marveled at the effortless gliding of birds through the skies. It is this inherent knack for utilizing wind patterns to their advantage that has served as the inspiration behind Morpho, the latest inspection drone developed by Elythor. By combining elements of both fixed-wing aircraft and quadcopters, Morpho emerges as a hybrid unmanned aerial vehicle (UAV) capable of adapting its shape to suit the task at hand.

The adaptive wings of Morpho play a pivotal role in extending the drone’s flight duration and enhancing its maneuverability. Equipped with embedded sensors and cameras, this cutting-edge drone can effortlessly navigate through confined spaces and open environments alike. As a result, it is perfectly suited for inspecting a wide range of critical infrastructure, including power plants, high-voltage power lines, wind turbines, gas pipelines, and offshore oil platforms.

Cutting costs by a third and reducing inspection time

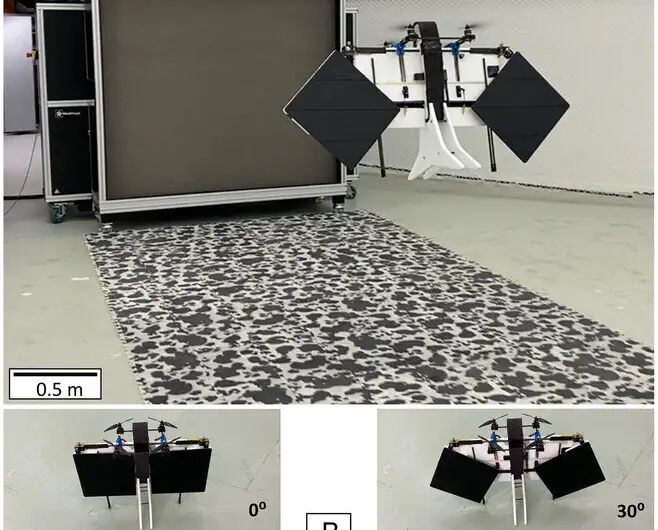

When at rest, Morpho assumes a sleek, rocket-like shape, resembling a miniature projectile. However, as soon as its rotors activate, a remarkable transformation takes place. This versatile drone possesses the ability to vertically take off, enabling its deployment in confined spaces where it can navigate within mere centimeters of equipment, conducting inspections without any collisions.

Upon completing an inspection, Morpho swiftly adapts by adjusting its motors and transitioning into a horizontal position, optimizing its aerodynamics for efficient flight to the next inspection site. In the face of strong or rapidly changing winds during its journey, the drone dynamically expands or contracts its wings to maintain a steady trajectory, even possessing the capability to glide under favorable wind conditions. This agility not only saves time during inspections but also extends the drone’s flight duration.

Harry Vourtsis, co-founder and CEO of Elythor, reveals that employing Morpho can reduce both the time and cost of drone inspections by an average of 35%. Once Morpho arrives at the subsequent inspection location, it effortlessly folds its wings and returns to a vertical position, enabling seamless proximity to the equipment. Vourtsis and his colleagues have shared their research on this extraordinary drone in an article published in Advanced Intelligent Systems.

Asymmetric wing adjustment provides stability in strong winds

According to Vourtsis, winged drones excel in longer flight durations, while quadcopters offer superior maneuverability. Elythor’s innovative approach combines the strengths of both types and incorporates an adaptive wing system that further reduces power requirements. Unlike most fixed-wing vertical take-off and landing (VTOL) drones, Morpho avoids compromising by having wings that are small enough to minimize friction during vertical flight and yet large enough to provide adequate lift during horizontal flight. This eliminates the challenge of VTOL drones struggling with take-offs and landings in strong winds due to their perpendicular surface area.

The development of Morpho’s wing control system stems from extensive research conducted at EPFL’s Laboratory of Intelligent Systems and has been extensively documented in scientific articles. This system integrates sensors that are connected to a software program, enabling real-time monitoring of wind direction and speed.

Nathan Müller, another co-founder at Elythor, explains the functionality of the controller: “Based on the drone’s trajectory, effective speed, and any changes in wind direction, the controller autonomously determines whether to keep the wings fixed or allow them to move in sync with the wind. Additionally, the wings’ surface area can be adjusted symmetrically or asymmetrically based on the wind direction.”

The control system algorithms not only optimize the balance between air friction and lift but also aim to minimize power consumption. This involves leveraging wind currents for gliding purposes and adjusting the wings asymmetrically to control the drone’s yaw or rotation around its vertical axis, enhancing stability during strong winds.

Quantitative assessments conducted at the EPFL lab demonstrate that Morpho exhibits remarkable maneuverability and power efficiency. Müller states, “Our design can reduce power usage by up to 85% when the drone is in vertical flight, while significantly enhancing its attitude and stability.” These advantages enable Morpho to conduct inspections across a wider range of weather conditions.

‘We want to revolutionize inspection platforms’

In its pursuit of offering customers a comprehensive solution, Elythor is actively involved in the development of software capable of compiling and analyzing the data collected by Morpho. Vourtsis emphasizes their vision to revolutionize inspection platforms, recognizing the current scenario where power plant operators employ different drone types depending on the location of the equipment to be inspected. With facilities spanning several kilometers and incorporating complex structures such as wind turbines and transmission towers, the need for a versatile solution becomes evident.

Elythor is diligently working towards finalizing the drone’s industrial production, with plans to make it market-ready by the end of this year. By combining cutting-edge technology, adaptable design, and advanced data analysis software, Elythor aims to provide a holistic and groundbreaking solution for inspection requirements.